MIT researchers say they’ve come up with an electric motor design with a power-to-weight ratio high enough to be practical in regional airliners. The team says they’ll get 17 kilowatts per kilogram out of the complex design, which means they can create a one megawatt motor that weighs just 125 pounds. “Many things together make the design possible, and the devil is in the details,” said researcher Zoltan Spakovsky.

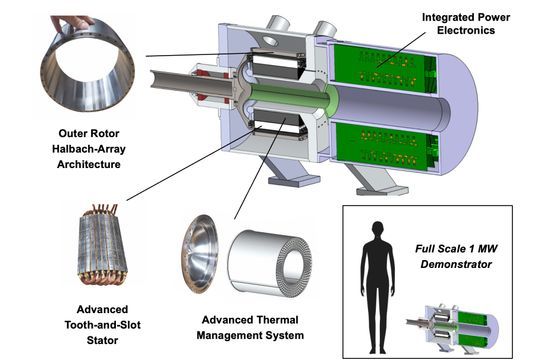

Physics dictates the basic design of all electric motors but the MIT design uses novel approaches to the design of the rotor and stator to allow the use of lighter materials especially in the rotor, which is the drum like structure in which the stator spins. A total of 30 circuit boards alternate the currents inside the motor at high frequency allowing it to spin at higher speeds than conventional designs. That means heat dissipation is an issue and an air-cooled heat exchanger inside the stator accomplishes that. The heat exchanger is so complex it has to be 3D printed..

Quote: “… especially in the rotor, which is the drum like structure in which the stator spins.”

It’s actually the opposite.

Oh, good. I DID remember it correctly.

As John Patson comments “stator static, rotor rotates.” That’s also true in this case but this is an OUTER rotor machine. The outer rotor spins and the inner stator is stationary. Quite the opposite of the usual motor but still rotor: rotating part and stator: stationary part.

Yip, stator static, rotor rotates.

Guessing it is a hot-rod synchronous motor similar to the Renault EV ones. (poor choice of words, I am sure their rotor will not get too hot…)

It is interesting that Mercedes has just bet big on Axial Flux (pancake) electric motors, for their small size, light weight and power.

Think they are the ones in Pipistrels also but could be wrong.

If you thought modern electronics transformed your ICE engines, just wait till it gets going on your electric motor…

For a detailed view of EV electric motor design, see munro live on you tube. Very enlightening and a good source for info on modern electric powerplants. My F150 Lightning’s electronic system is reminiscent of a modern transport category airplane I used to fly; complex, complicated, EICAS-like. The battery and motor cooling system works well, so far, but that’s a lot of added weight for an airplane.

Ya-but . . . batteries.

Continuing improvement of motors, control & aerodynamics at least means when that promised miracle is announced we’ll be ready.

Yea, but…

Now that we’ve got a motor that is more powerful, that increases the gap between practical and current battery tech. So this advancement ( and without a doubt it is an advancement) has the effect of giving those working on battery tech an even bigger hill to climb.

The choice to research this project with the current state of battery tech shows the stupidity promoted by academia under the guise of research. Building something that is only functional in either the future or a fantasy is a waste of time and resources. The word “folly” springs to mind. That time and those resources should have been put toward battery tech.

Of course now that this crew has finished this project maybe they’re the folks to tackle the battery question.

Hey if batteries can catch fire, now motors are on the line for burning out too. LOL.

Well, jokes on the side, it’s nice to see all the effort put on technology development for EVs That’s the way to go. I can’t wait to see graphene cheap enough to start being used on airplane structures and electronic components as well. That would be “The Dream” : )

Re: Rotors vs. stators: Traditionally, rotors had fixed magnets which rotated inside of a fixed stator, which used electromagnets to generate a rotating magnetic field. In this case, the rotor – with its permanent magnets – is fixed; the stator – with its rotating magnetic field – is what spins.

Not unlike a rotary aircraft engine as compared to a radial. Everything old is new again.

The outer drum which contains the permanent magnets is what rotates in this design.

The Halbach array is relatively interesting. A common use is in rubberized refrigerator magnets. Find 2 that are the same. They will only attract one another back to back. When you slide them against each other, they have a notchey feel. Halbach arrays are easy to make with low strength ferrite magnets but not so easy to make using high strength rare earth magnets

“The outer drum which contains the permanent magnets is what rotates in this design.”

I stand corrected.

Some of the most powerful but compact and (relatively) light transportation electric motors are used in the Lucid high tech EV’s.

It’s a small company with some forward thinking people.

If you have never heard of Lucid Google them and check out their Electric Motors.

Yep, Lucid manufactures a high-end (higher than Tesla Model S) all-electric luxury car. Very nice (a friend has one). The range is exceptional at nearly 500 miles per charge. Last time I was in it, my friend said the car was great, but the software that ran everything was not really up to the level it should be. His Tesla’s control software was much more sophisticated. (Yes, he has one of each – he’s a doctor and a car nut) Fortunately this software can be upgraded on the fly, so he was hopeful it would improve.

So, why does the outer drum have the mounting feet and wiring connections if it rotates?

“Outer” drum is a bit of a misnomer, as it is entirely within the motor housing (which is also drum shaped).

The term comes about because the rotor wraps around the stator when normally the stator would be a drum around the rotor.

I love innovation.